SPOT WELDING - OLEODYNAMIC PRESSES

13001

code

AUTOMATIC PIPE CALIBRATION MACHINE.

- PRESS CALIBRATING MACHINE 4000TON TO CALIBRATE WELDED TUBES (MADE FROM METAL) FROM DIA. A 168MM DIA. 1250MM THICKNESS FROM 10MM TO 70MM STAINLESS STEEL

– DUPLEX

- SUPERDUPLEX

- POWER EXTRACTION 250TON

- LOAD HANDLING ON A ROLLER TUBE ANTERIOR AND POSTERIOR

- TRANSLATION AND ROTATION PIPE FULLY AUTOMATED WITHOUT A CRANE

- WITH POWER PULLER 50TON POSITION ON THE PLAN MOBILE

- MOVING OUT OF AUTOMATED MOULD DIE LOCK HYDRAULIC OPERATION UNLOADING / LOAD PRACTICABLE DIES IN 5 MINUTES WITH MAXIMUM DIE ALREADY PLACED

- TOTAL POWER ENGINE INSTALLED ABOUT 300KW

- ALL INSTALLED ENGINES ARE EQUIPPED WITH INVERTER THAT ALLOW AN ENERGY SAVING UP TO 50%.

– DUPLEX

- SUPERDUPLEX

- POWER EXTRACTION 250TON

- LOAD HANDLING ON A ROLLER TUBE ANTERIOR AND POSTERIOR

- TRANSLATION AND ROTATION PIPE FULLY AUTOMATED WITHOUT A CRANE

- WITH POWER PULLER 50TON POSITION ON THE PLAN MOBILE

- MOVING OUT OF AUTOMATED MOULD DIE LOCK HYDRAULIC OPERATION UNLOADING / LOAD PRACTICABLE DIES IN 5 MINUTES WITH MAXIMUM DIE ALREADY PLACED

- TOTAL POWER ENGINE INSTALLED ABOUT 300KW

- ALL INSTALLED ENGINES ARE EQUIPPED WITH INVERTER THAT ALLOW AN ENERGY SAVING UP TO 50%.

27005

code

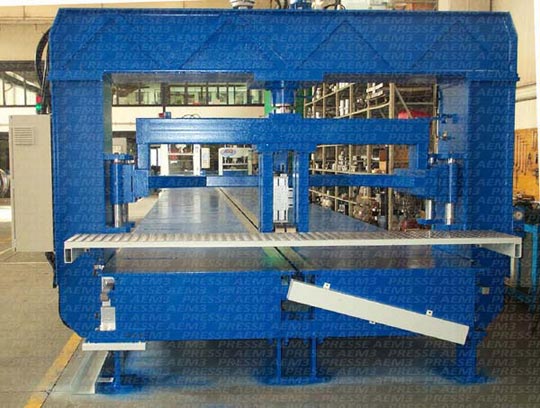

PRESSES FOR STRAIGHTENING PLATE.

- SPAN BETWEEN PILLARS 2720 mm.

- PERFECT FOR WELDING PLATE WITH DIFFERENT THICKNESS AND MATERIAL UP TO 13500 mm. LONG (CUSTOM MADE)

- PRESSES WITH FLOATING CYLINDER AND SUPPORT PRESSES WITH COILS.

- PERFECT FOR WELDING PLATE WITH DIFFERENT THICKNESS AND MATERIAL UP TO 13500 mm. LONG (CUSTOM MADE)

- PRESSES WITH FLOATING CYLINDER AND SUPPORT PRESSES WITH COILS.

26032

code

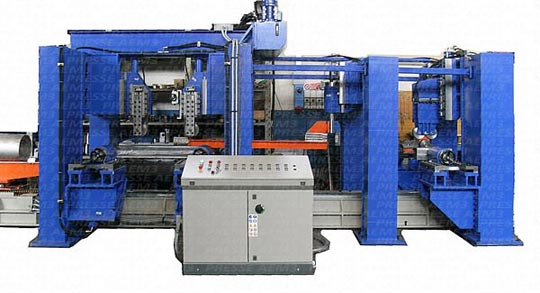

PRESSES USED TO BEND STEEL PIPES.

- “PILLAR” PRESS WITH “LINEAR” BEARINGS

- USED FOR MANUFACTURING WELDED PIPES IN DUPLEX AND SUPER DUPLEX STAINLESS STEEL UP TO 40 mm. THICK SPAN OF THE OPEN CYLINDER – WORK TABLE 1500 mm.

- FRONT SPAN (OPERATOR’S SIDE) 1800 mm. NON HORIZONTAL LATERAL SPAN 1400 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- SPEED 200/10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION

- COMPLETE WITH FOUR 20TON CYLINDERS STROKE 650MM FOR PIPE-IN-PROCESS EXTRACTION AND ROTATION (TWO PLACED ON THE MOVING PLANE AND TWO PLACED ON THE LOWER FIXED PLANE)

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES AND BIMANUAL PUSH-BUTTON CONTROL PANELS

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE BACK SIDE WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES PIPE-SIZING PRESSES.

- USED FOR MANUFACTURING WELDED PIPES IN DUPLEX AND SUPER DUPLEX STAINLESS STEEL UP TO 40 mm. THICK SPAN OF THE OPEN CYLINDER – WORK TABLE 1500 mm.

- FRONT SPAN (OPERATOR’S SIDE) 1800 mm. NON HORIZONTAL LATERAL SPAN 1400 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- SPEED 200/10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION

- COMPLETE WITH FOUR 20TON CYLINDERS STROKE 650MM FOR PIPE-IN-PROCESS EXTRACTION AND ROTATION (TWO PLACED ON THE MOVING PLANE AND TWO PLACED ON THE LOWER FIXED PLANE)

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES AND BIMANUAL PUSH-BUTTON CONTROL PANELS

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE BACK SIDE WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES PIPE-SIZING PRESSES.

27003

code

PRESSES FOR HYDRAULIC PIPES.

- PRESSES USED TO EXPAND HYDRAULIC PIPES “PILLAR” PRESS WITH “LINEAR” BEARINGS

- USED FOR MANUFACTURING DUPLEX AND SUPER DUPLEX WELDED

- STAINLESS STEEL PIPES UP TO 60 mm. THICK 2500 ton. POWER

- FRONT SPAN (OPERATOR’S SIDE) 2250 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- OPEN CYLINDER SPAN

- WORK TABLE 2000 mm.

- SPEED 200/10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION COMPLETE WITH 2 70 TON CYLINDERS 650MM STROKE FOR PIPE-IN-PROCESS ROTATION

- COMPLETE WITH 2 20 ton. CYLINDERS 650 mm. STROKE FOR PIPE-IN-PROCESS EXTRACTION PLACED ON THE MOVING PLANE

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES AND BIMANUAL PUSH-BUTTON CONTROL PANELS

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

- USED FOR MANUFACTURING DUPLEX AND SUPER DUPLEX WELDED

- STAINLESS STEEL PIPES UP TO 60 mm. THICK 2500 ton. POWER

- FRONT SPAN (OPERATOR’S SIDE) 2250 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- OPEN CYLINDER SPAN

- WORK TABLE 2000 mm.

- SPEED 200/10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION COMPLETE WITH 2 70 TON CYLINDERS 650MM STROKE FOR PIPE-IN-PROCESS ROTATION

- COMPLETE WITH 2 20 ton. CYLINDERS 650 mm. STROKE FOR PIPE-IN-PROCESS EXTRACTION PLACED ON THE MOVING PLANE

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES AND BIMANUAL PUSH-BUTTON CONTROL PANELS

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

27060

code

PIPE FORMING SYSTEMS.

- “PILLAR” PRESS WITH “LINEAR” BEARINGS

- USED FOR MANUFACTURING WELDED DUPLEX AND SUPER DUPLEX STAINLESS STEEL PIPES

- MAXIMUM 60 mm. THICK

- POWER 3500 ton.

- FRONT SPAN (OPERATOR’S SIDE) 2250 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- SPAN BETWEEN OPEN CYLINDER AND WORK TABLE 2000 mm.

- SPEED 200/10/200 mm/sec.

- PRESS WITH SLIDING GUIDES

- COMPLETE WITH TWO 200 ton CYLINDERS STROKE 600 mm. FOR STRAIGHTENING THE PIPE-IN-PROCESS

- COMPLETE WITH FOUR 20 ton. CYLINDERS STROKE 650 mm. FOR ROTATION AND SLIDING OF THE PIPE-IN-PROCESS

- COMPLETE WITH TWO 20 ton. CYLINDERS STROKE 650 mm. FOR EXTRACTION OF THE PIPE-IN-PROCESS PLACED ON THE MOBILE PLANE

- COMPLETE ALSO WITH MOULD LOADING /UNLOADING

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

- USED FOR MANUFACTURING WELDED DUPLEX AND SUPER DUPLEX STAINLESS STEEL PIPES

- MAXIMUM 60 mm. THICK

- POWER 3500 ton.

- FRONT SPAN (OPERATOR’S SIDE) 2250 mm.

- DEPTH SPAN (LATERAL SIDE) 1500 mm.

- SPAN BETWEEN OPEN CYLINDER AND WORK TABLE 2000 mm.

- SPEED 200/10/200 mm/sec.

- PRESS WITH SLIDING GUIDES

- COMPLETE WITH TWO 200 ton CYLINDERS STROKE 600 mm. FOR STRAIGHTENING THE PIPE-IN-PROCESS

- COMPLETE WITH FOUR 20 ton. CYLINDERS STROKE 650 mm. FOR ROTATION AND SLIDING OF THE PIPE-IN-PROCESS

- COMPLETE WITH TWO 20 ton. CYLINDERS STROKE 650 mm. FOR EXTRACTION OF THE PIPE-IN-PROCESS PLACED ON THE MOBILE PLANE

- COMPLETE ALSO WITH MOULD LOADING /UNLOADING

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

28015

code

PRESSES FOR SPOT WELDING PIPES.

- EQUIPMENT USED TO WELD PIPES

- PRESSES FOR SPOT WELDING PIPES UP TO 50 mm THICK

- A SERIES OF CYLINDERS WITH 350 TON POWER THEY ALLOW PIPE TO BE CLOSED

- MINIMUM DIAMETER 160 mm, MAXIMUM DIAMETER 750 mm.

- MAXIMUM THICKNESS 50 mm FOR STAINLESS STEEL.

- PRESSES FOR SPOT WELDING PIPES UP TO 50 mm THICK

- A SERIES OF CYLINDERS WITH 350 TON POWER THEY ALLOW PIPE TO BE CLOSED

- MINIMUM DIAMETER 160 mm, MAXIMUM DIAMETER 750 mm.

- MAXIMUM THICKNESS 50 mm FOR STAINLESS STEEL.

27006

code

ROLLER PRESS - PRESSES FOR SPOT WELDING LOW THICKNESS PIPES.

- PERFECT FOR MANUFACTURING PIPES WITH MINIMUM 200 mm DIAMETERS AND MAXIMUM 760 mm DIAMETERS AND MAXIMUM THICKNESS OF 4 TO 6 mm FOR STAINLESS STEEL

- PRESSES USED TO WELD HYDRAULIC PIPES.

- PRESSES USED TO WELD HYDRAULIC PIPES.