AUTOMOTIVE INDUSTRY - HYDRAULIC PRESSES

21x10/11

code

200/100 tons hot forging presses for automotive interiors.

Front protection PHOTOELECTRIC BARRIERS

Rear protection PHOTOELECTRIC BARRIERS

Right side protection CLOSED STRUCTURE

Left side protection CLOSED STRUCTURE

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 20/12 KW

Thrust force of main cylinder 200/100 Tonn

Operator side horizontal light 2900 mm

Vertical light 900 mm

Main cylinder stroke 700 mm

Height of the worktop from the ground 825 mm

Dimension of the lower worktop 2600x1700 mm

Dimension of the mobile worktop 2600x1700 mm

Fast descent speed 100 mm / sec

Working speed 5 mm / sec

Fast ascent speed 100 mm / sec

20x11

code

Presses for automotive.

Press supplied as ALMOST MACHINE without electrical systems and protections

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 55 KW

Main cylinder thrust force 50 Tons

Operator side horizontal light 2610 mm

Side horizontal light 1240 mm

Vertical light 2000 mm

Main cylinder stroke 1200 mm

Height of the worktop from the ground 500 mm

Dimension of the lower worktop 2600x1700 mm

Dimension of the mobile worktop 2600x1700 mm

Fast descent speed 200 mm / sec

Working speed 5 mm / sec

Fast ascent speed 200 mm / sec

18025

code

Press with heating plates for molding car pavilions.

Press complete with heating plates

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 55 KW

Thrust force of main cylinder 100 Tons

Operator side horizontal light 2700 mm

Lateral horizontal light 2000 mm

Vertical light 1400 mm

Main cylinder stroke 1200 mm

Height of the worktop from the ground 1100 mm

Lower worktop size 3200x1600 mm

Mobile worktop size 3200x1600 mm

Fast descent speed 350 mm / sec

Working speed 3.5 mm / sec

Fast ascent speed 350 mm / sec

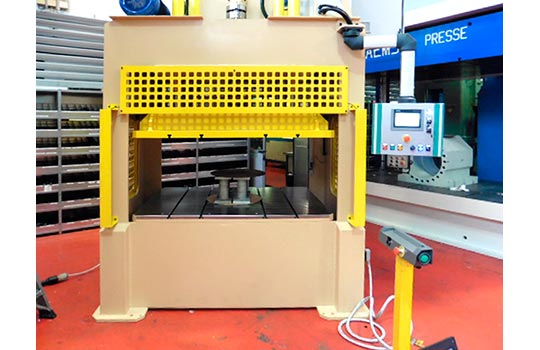

22076

code

PRESS 260 tonn.

- POWER tonn.260

- FRONT LIGHT PROFIT between COLUMNS mm. 2700

- LIGHT SIDE NET between COLUMNS mm. 1200

- LIGHT between PLANS OPEN mm. 1700

- STROKE MOBILE PLAN mm. 1000

- SPEED CLOSED/OPEN mm./sec. 250

- SPEED WORK ADJUSTABLE mm./sec. 10

- DISTANCE from LAND of the WORK PLAN mm. 650/850

The press has automatic and manual cycle to cycle, and is equipped with a control panel with a keyboard that can be set and displayed data and readable by means of a liquid crystal display is easy to read, PC controller.

OPTIONAL ON REQUEST:

The press can be provided with a plate recipe pillow that allows:

- In phase of work as a cushion blank holder a force of adjustable contrast of 50 tons. maximum with a stroke of 100 mm.

- In the work phase extractor as a force of adjustable thrust of a maximum of 50 tons.

- FRONT LIGHT PROFIT between COLUMNS mm. 2700

- LIGHT SIDE NET between COLUMNS mm. 1200

- LIGHT between PLANS OPEN mm. 1700

- STROKE MOBILE PLAN mm. 1000

- SPEED CLOSED/OPEN mm./sec. 250

- SPEED WORK ADJUSTABLE mm./sec. 10

- DISTANCE from LAND of the WORK PLAN mm. 650/850

The press has automatic and manual cycle to cycle, and is equipped with a control panel with a keyboard that can be set and displayed data and readable by means of a liquid crystal display is easy to read, PC controller.

OPTIONAL ON REQUEST:

The press can be provided with a plate recipe pillow that allows:

- In phase of work as a cushion blank holder a force of adjustable contrast of 50 tons. maximum with a stroke of 100 mm.

- In the work phase extractor as a force of adjustable thrust of a maximum of 50 tons.

16018

code

"A 4-COLUMN" PRESS BRAND "AEM3" CONSTRUCTION YEAR 1998 REFURBISHED AND COMPLETELY RESTORED TO NEW. THIS CUSTOMER WORKS IN THE AUTOMOTIVE SECTOR AND PRODUCES REPAIR HEATS FOR AUTOMOTIVE COMPANIES SUCH AS "FERRARI / LAMBIORGHINI / AUDI / BMW / FIAT / ALFA ROMEO" AND MANY OTHER CASES OF THE MOST MAIN.

-

- THE PARTICULARITY OF THIS PRESS IS THAT IT COMES FROM THE BOTTOM TOWARDS THE TOP AND ITS DIMENSIONS ARE THE FOLLOWING:

- POWER 100TON

- LIGHT BETWEEN THE COLUMNS 2300X1300MM

- LIGHT AMONG THE OPEN PLANS 1200MM

- LIGHT BETWEEN CLOSED WORKTOPS 150MM

- 600MM PISTON STROKE

- THIS PRESS HAS THE POSSIBILITY TO MOVE THE UPPER TOP IN DIFFERENT HEIGHTS UP TO A MAXIMUM OF 5 HOLES OF 150MM DISTANCE THEREFORE BRINGING THE LIGHT BETWEEN THE OPEN WORKTOPS MINIMUM TO 750MM INSTEAD OF 1200MM

- ASCENT / DESCENT SPEED 350MM / SEC

- WORKING SPEED 25MM / SEC

- OVERALL DIMENSIONS 3000X4500X3100MM (WIDTH X DEPTH X HEIGHT)

- WEIGHT 15.000KG

17018

code

AUTOMOTIVE PRESSES.

- PUSH POWER 50 Ton.

- TRACTION POWER 25 Ton.

- CYLINDER STROKE 600 mm.

- DIMENSION WORKING PLAN 2000x1500 mm.

- VERTICAL LIGHT 1000 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

- TRACTION POWER 25 Ton.

- CYLINDER STROKE 600 mm.

- DIMENSION WORKING PLAN 2000x1500 mm.

- VERTICAL LIGHT 1000 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

17019

code

AUTOMOTIVE PRESSES.

-PUSH POWER 20 Ton.

- TRACTION POWER 10 Ton.

- CYLINDER STROKE 600 mm.

- WORKING PLANE DIMENSION 1600x1200 mm.

- VERTICAL LIGHT 800 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

- TRACTION POWER 10 Ton.

- CYLINDER STROKE 600 mm.

- WORKING PLANE DIMENSION 1600x1200 mm.

- VERTICAL LIGHT 800 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

17025

code

AUTOMOTIVE PRESSES.

- PUSH POWER 100 Ton.

- TRACTION POWER 50 Ton.

- CYLINDER STROKE 1000 mm.

- WORKING PLAN DIMENSION 2500x1400 mm.

- VERTICAL LIGHT 1600 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

- TRACTION POWER 50 Ton.

- CYLINDER STROKE 1000 mm.

- WORKING PLAN DIMENSION 2500x1400 mm.

- VERTICAL LIGHT 1600 mm.

- DOWNWIND SPEED AND QUICK UP 200 mm / sec.

- WORKING SPEED 2-10 mm / sec.

28023

code

PRESSES FOR RUBBER.

- “4 COLUMN” PRESS

- POWER 2000 ton. SPAN 2000x2000x1800 mm. CYLINDER STROKE 1100 mm.

- SPEED 200/50/10-5/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION COMPLETE WITH EIGHT 20 ton. UPPER AND LOWER EXTRACTORS

- STROKE 100 mm.

-SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES, WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE OPERATOR’S BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES

- PRESS WITH UPPER BLANK HOLDER CUSHION.

- POWER 2000 ton. SPAN 2000x2000x1800 mm. CYLINDER STROKE 1100 mm.

- SPEED 200/50/10-5/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION COMPLETE WITH EIGHT 20 ton. UPPER AND LOWER EXTRACTORS

- STROKE 100 mm.

-SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES, WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE OPERATOR’S BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES

- PRESS WITH UPPER BLANK HOLDER CUSHION.

11012

code

GASKET PRESSES.

- 400 ton. OPEN SHOULDER OLEO-DYNAMIC PRESS WITH OLEO-DYNAMIC SYNCHRONIZING SYSTEM FOR ALL 4 CYLINDERS FOUR 100 ton. EACH DOUBLE-ACTING HYDRAULIC CYLINDERS + TWO 25 ton. CYLINDERS FOR QUICK UPSTROKE

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATING SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- MAXIMUM OPERATING PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1400 mm.

- WORKING DIMENSIONS OF THE WORK TABLE (HEATED TO 210°) 3000X1600 mm.

- DISTANCE BETWEEN OPEN SHOULDERS 3400X3000 mm.

- TOTAL PRESS HEIGHT 7500 mm.

- WEIGHT 80000 Kg.

- PRESS FOR COMPOSITE MATERIALS.

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATING SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- MAXIMUM OPERATING PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1400 mm.

- WORKING DIMENSIONS OF THE WORK TABLE (HEATED TO 210°) 3000X1600 mm.

- DISTANCE BETWEEN OPEN SHOULDERS 3400X3000 mm.

- TOTAL PRESS HEIGHT 7500 mm.

- WEIGHT 80000 Kg.

- PRESS FOR COMPOSITE MATERIALS.

11014

code

PRESSES FOR AUTOMATED SYSTEMS.

- 400 ton. OPEN SHOULDER OLEO-DYNAMIC PRESS

- 400 ton. 4 COLUMN OLEO-DYNAMIC

- PRESS WITH OLEO-DYNAMIC SYNCHRONIZING SYSTEM FOR ALL 4 CYLINDERS FOUR DOUBLE-ACTING HYDRAULIC CYLINDERS 100 TONS EACH + TWO 25 ton. CYLINDERS FOR QUICK UPSTROKE

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATING SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- OPERATING MAXIMUM PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1500 mm.

- WORKING DIMENSIONS OF THE WORK TABLE = 3700X1800 mm.

- DISTANCE BETWEEN COLUMNS 3500X2000 mm.

- TOTAL PRESS HEIGHT 6800 mm.

- WEIGHT 75000 Kg.

- 400 ton. 4 COLUMN OLEO-DYNAMIC

- PRESS WITH OLEO-DYNAMIC SYNCHRONIZING SYSTEM FOR ALL 4 CYLINDERS FOUR DOUBLE-ACTING HYDRAULIC CYLINDERS 100 TONS EACH + TWO 25 ton. CYLINDERS FOR QUICK UPSTROKE

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATING SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- OPERATING MAXIMUM PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1500 mm.

- WORKING DIMENSIONS OF THE WORK TABLE = 3700X1800 mm.

- DISTANCE BETWEEN COLUMNS 3500X2000 mm.

- TOTAL PRESS HEIGHT 6800 mm.

- WEIGHT 75000 Kg.

11013

code

PRESSES FOR THE AUTOMOTIVE INDUSTRY.

- SPECIAL AERONAUTICAL SYSTEMS

- 100 ton. 4 COLUMN OLEO-DYNAMIC PRESS WITH OLEO-DYNAMIC SYNCHRONIZING SYSTEM FOR ALL 4 CYLINDERS FOUR DOUBLE-ACTING HYDRAULIC CYLINDERS OF 25 TONS EACH ONE

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATOR SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- MAXIMUM PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1400 mm.

- WORKING DIMENSIONS OF THE WORK TABLE (TOP PART HEATED TO 210°) 3220X1600 mm.

- DISTANCE BETWEEN COLUMNS 2700X2000 mm.

- TOTAL PRESS HEIGHT 6200 mm.

- WEIGHT 45000 Kg.

- 100 ton. 4 COLUMN OLEO-DYNAMIC PRESS WITH OLEO-DYNAMIC SYNCHRONIZING SYSTEM FOR ALL 4 CYLINDERS FOUR DOUBLE-ACTING HYDRAULIC CYLINDERS OF 25 TONS EACH ONE

- DOWN STROKE / UPSTROKE SPEED 300 mm/sec.

- OPERATING SPEED 0.1 to 5 mm/sec.

- EQUIPPED WITH ACCUMULATOR SYSTEMS FOR QUICK DOWN AND UPSTROKE ACTION

- MAXIMUM PRESSURE 200 BAR

- CYLINDER STROKE 1200 mm.

- SPAN BETWEEN OPEN SURFACES 1400 mm.

- WORKING DIMENSIONS OF THE WORK TABLE (TOP PART HEATED TO 210°) 3220X1600 mm.

- DISTANCE BETWEEN COLUMNS 2700X2000 mm.

- TOTAL PRESS HEIGHT 6200 mm.

- WEIGHT 45000 Kg.

16006

code

THIS CUSTOMER WORKS IN THE "AUTOMOTIVE" SECTOR FOR "PIAGGIO / CAGIVA / DUCATI / ECC ....." .

60TON SWAN NECK PRESS

RECESS 310MM

300MM PISTON STROKE

LIGHT BETWEEN THE OPEN WORKTOPS 600MM

700x500MM PLATES

SPEED OF DESCENT 100MM / SEC

WORKING SPEED 3MM / SEC

RETURN SPEED 120MM / SEC

CONTROL OF THE PRESS WITH "SELF-LEARNING" ELECTRODISTRIBUTOR WITH TOUCH SCREEN BRAND "PROFACE" AND PLC SIEMENS, WITH THE POSSIBILITY TO SET UP ALTITUDE / DECELERATION ALTITUDE / DESCENT ALTITUDE / DECELERATION ALTITUDE / PRESSURE AND DISPLAY ALTITUDE >

COMPLETE WITH LEVEL IV OPTICAL BARRIERS ON THE OPERATOR SIDE AND FIXED NETWORK PROTECTION ON THE REMAINING SIDES

CONTROL UNIT RECESSED INSIDE THE STRUCTURE TO CONTAIN THE OVERALL SPACES OF THE PRESS itself

OVERALL DIMENSIONS 1.100x2.000x2.450 (WIDTH x DEPTH x HEIGHT)

WEIGHT KG. 6,500

28004

code

HYDRAULIC BURR BLANKING PRESSES.

- “4 COLUMN” PRESS

- POWER 200 ton.

- SPAN 2500x1350x2000 mm.

- STROKE 1250 mm.

- SPEED 400/15/400 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE OPERATOR’S BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

- POWER 200 ton.

- SPAN 2500x1350x2000 mm.

- STROKE 1250 mm.

- SPEED 400/15/400 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND ON THE OPERATOR’S BACK SIDE AND WITH FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

27031

code

PHOTOVOLTAIC PANEL PRESSES.

- “4 COLUMN” PRESS

- PRESS EQUIPPED WITH TWO PISTONS WITH 120 ton. OVERALL POWER

- SPAN 2000x1800x1200 mm.

- STROKE 1000 mm.

- SPEED 200/5-10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION - SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES - LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL PLASTIC MOULDING PRESS.

- PRESS EQUIPPED WITH TWO PISTONS WITH 120 ton. OVERALL POWER

- SPAN 2000x1800x1200 mm.

- STROKE 1000 mm.

- SPEED 200/5-10/200 mm/sec.

- ELECTRONIC WORKING SPEED REGULATION - SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES - LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL PLASTIC MOULDING PRESS.

25009

code

DRAWING HYDRAULIC PRESSES.

- “4 COLUMN” PRESS

- POWER 70 ton.

- SPAN 2000x1000x2000 mm.

- STROKE 1250 mm.

- SPEED 500/50/10/500 mm/sec.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL.

- POWER 70 ton.

- SPAN 2000x1000x2000 mm.

- STROKE 1250 mm.

- SPEED 500/50/10/500 mm/sec.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL.

21010

code

PVC PANEL PRESSES.

- “4 COLUMN” PRESS

- POWER 60 ton.

- SPAN 2000X700X1500 mm.

- STROKE 1000 mm.

- SPEED 200/10/200 mm/sec.

- EQUIPMENT WITH PROPORTIONAL SOLENOID VALVE WITH THREE MANUFACTURING CYCLES: MANUAL, SEMIAUTOMATIC, AUTOMATIC AND WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

- POWER 60 ton.

- SPAN 2000X700X1500 mm.

- STROKE 1000 mm.

- SPEED 200/10/200 mm/sec.

- EQUIPMENT WITH PROPORTIONAL SOLENOID VALVE WITH THREE MANUFACTURING CYCLES: MANUAL, SEMIAUTOMATIC, AUTOMATIC AND WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES.

2032

code

PRESSES FOR COVERINGS.

- “PILLAR” PRESS

- POWER 200 ton.

- SPAN 1500X700x700 mm.

- STROKE 500 mm.

- SPEED 60/5/60 mm/sec.

- COMPLETE WITH 100 ton. BLANK HOLDER

- STROKE 300 mm. WITH 52 HOLES FOR 40 mm. DIAMETER ELECTRODES

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- PRESSES WITH PARALLELISM TOLERANCE.

- POWER 200 ton.

- SPAN 1500X700x700 mm.

- STROKE 500 mm.

- SPEED 60/5/60 mm/sec.

- COMPLETE WITH 100 ton. BLANK HOLDER

- STROKE 300 mm. WITH 52 HOLES FOR 40 mm. DIAMETER ELECTRODES

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES

- LEVEL IV PROTECTION BARRIERS ON THE OPERATOR’S SIDE AND AT THE BACK SIDE WITH BIMANUAL PUSH-BUTTON CONTROL PANEL

- PRESSES WITH PARALLELISM TOLERANCE.