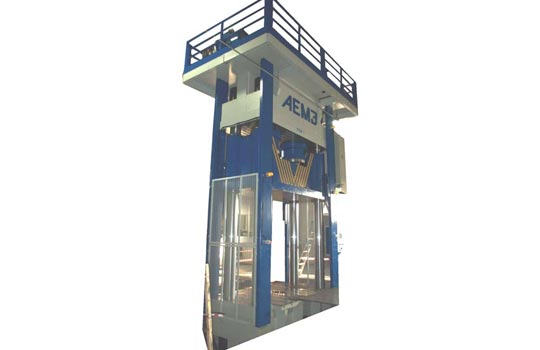

FORGING PRESSES - OLEODYNAMIC PRESSES

21x30/31

code

Hydroforming press 1500 tons.

Front protection PHOTOELECTRIC BARRIERS

Rear protection CLOSED IN WORK ISLAND

Right side protection CLOSED IN WORK ISLAND

Left side protection CLOSED IN WORK ISLAND

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 65 KW

Thrust force of the main cylinder 1500 Tons

Operator side horizontal light 2000 mm

Side horizontal light 1070 mm

Vertical light 1300 mm

Main cylinder stroke 700 mm

Height of the worktop from the ground 1050 mm

Lower worktop size 2000x1000 mm

Mobile worktop size 2000x1000 mm

Fast descent speed 200 mm / sec

Working speed 5-12 mm / sec

Fast ascent speed 200 mm / sec

Hydroforming press 800 tons.

Front protection PHOTOELECTRIC BARRIERS

Rear protection CLOSED IN WORK ISLAND

Right side protection CLOSED IN WORK ISLAND

Left side protection CLOSED IN WORK ISLAND

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 60 KW

Thrust force of main cylinder 800 Tons

Operator side horizontal light 1335 mm

Side horizontal light 980 mm

Vertical light 1300 mm

Main cylinder stroke 800 mm

Height of the worktop from the ground 1000 mm

Dimension of the lower worktop 1300x1000 mm

Dimension of the mobile worktop 1300x1000 mm

Fast descent speed 200 mm / sec

Working speed 5-12 mm / sec

Fast ascent speed 200 mm / sec

21x15

code

Press for molding 1000 tons.

Lower floor - machining / slots for T nuts on customer request

Movable table - machining / slots for T nuts at the customer's request

Installed power 34 KW

Thrust force of main cylinder 1000 Tons

Operator side horizontal light 1500 mm

Vertical light 1000 mm

Main cylinder stroke 400 mm

Height of the worktop from the ground 800 mm

Dimension of the lower worktop 1500x1440 mm

Dimension of the mobile worktop 1430x1480 mm

Rapid descent speed 25 mm / sec

Working speed 5 mm / sec

Rapid rise speed 25 mm / sec

18003

code

PRESS SUITABLE FOR WORKING OF HOT FORGING IN BRASS PARTS AND COLD STAMPING OF METAL PARTS.

- PRESS AT "SHOULDERS CLOSED" WITH PRISMATIC GUIDES

- POWER 1000TON

- USEFUL WORKING PLAN 1500x1500MM

- LIGHT AMONG PISTON AND WORKING PLAN 900MM

- STROKE PISTON 400MM

- APPROXIMATION SPEED 200MM / SEC

- WORKING SPEED ADJUSTABLE AUTOMATICALLY ACCORDING TO THE POWER THAT IS 25-5MM / SEC

- RETURN SPEED 200MM / SEC

- PRESS EQUIPPED WITH BLANK HOLDER 300TON STROKE 200MM WITH WORKTOP 860x420MM

- WORKING PLAN INFERIOR EQUIPPED WITH N ° 40 HOLES DIAM. 40MM FOR CANDLE PASSAGE

- PRESS EQUIPPED WITH SELF-LEARNING SYSTEM WITH "SIEMENS" PLC AND TOUCH SCREEN BRAND "PRO FACE"

- POSSIBILITY TO SAVE UP TO 200 DIFFERENT PROGRAMS

- DENISON / PARKER HYDRAULIC SYSTEM

- OPTICAL BARRIERS OF LEVEL IV BRAND "KEYENCE" MOUNTED ON THE OPERATOR SIDE AND FIXED PROTECTION ON THE NET ON THE OPPOSITE OPERATOR SIDE

- ENGINES INSTALLED WITH TOTAL POWER OF ABOUT 95kW

- OVERALL DIMENSIONS PRESSING 3.300x2.500x5.500mm

- WEIGHT 40.000Kg

- POWER 1000TON

- USEFUL WORKING PLAN 1500x1500MM

- LIGHT AMONG PISTON AND WORKING PLAN 900MM

- STROKE PISTON 400MM

- APPROXIMATION SPEED 200MM / SEC

- WORKING SPEED ADJUSTABLE AUTOMATICALLY ACCORDING TO THE POWER THAT IS 25-5MM / SEC

- RETURN SPEED 200MM / SEC

- PRESS EQUIPPED WITH BLANK HOLDER 300TON STROKE 200MM WITH WORKTOP 860x420MM

- WORKING PLAN INFERIOR EQUIPPED WITH N ° 40 HOLES DIAM. 40MM FOR CANDLE PASSAGE

- PRESS EQUIPPED WITH SELF-LEARNING SYSTEM WITH "SIEMENS" PLC AND TOUCH SCREEN BRAND "PRO FACE"

- POSSIBILITY TO SAVE UP TO 200 DIFFERENT PROGRAMS

- DENISON / PARKER HYDRAULIC SYSTEM

- OPTICAL BARRIERS OF LEVEL IV BRAND "KEYENCE" MOUNTED ON THE OPERATOR SIDE AND FIXED PROTECTION ON THE NET ON THE OPPOSITE OPERATOR SIDE

- ENGINES INSTALLED WITH TOTAL POWER OF ABOUT 95kW

- OVERALL DIMENSIONS PRESSING 3.300x2.500x5.500mm

- WEIGHT 40.000Kg

25054

code

SYSTEM FORMING PIPES HOT.

- POWER 1500 ton.

- SPAN 2500x600x2600 mm.

- COLUMN DIAM. 400 mm.

- STROKE 1800 mm.

- SPEED DOWN / UP 100 mm/sec.

- SPEED WORK 15 mm/sec.

- POWER INSTALLATION 200 kW

- COMPLETE WITH 250 ton. LOWER BLANK HOLDER STROKE 2300 mm.

- COMPLETE WITH EXTERNALLY SLIDING BOLSTER TO CHANGE MOULDS TO 830X1350X110 mm.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES LEVEL IVPROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL.

- SPAN 2500x600x2600 mm.

- COLUMN DIAM. 400 mm.

- STROKE 1800 mm.

- SPEED DOWN / UP 100 mm/sec.

- SPEED WORK 15 mm/sec.

- POWER INSTALLATION 200 kW

- COMPLETE WITH 250 ton. LOWER BLANK HOLDER STROKE 2300 mm.

- COMPLETE WITH EXTERNALLY SLIDING BOLSTER TO CHANGE MOULDS TO 830X1350X110 mm.

- SELF-LEARNING EQUIPMENT WITH DATA STORAGE AND OTHER ACCESSORIES LEVEL IVPROTECTION BARRIERS ON THE OPERATOR’S SIDE AND FIXED WIRE MESH PROTECTION ON THE REMAINING PRESS’S SIDES WITH BIMANUAL PUSH-BUTTON CONTROL PANEL.

12020

code

Press "LASKO".

- Press which rises from the bottom upwards

- Light between the shoulders on the operator side 2100 mm.

- Light between floors open 5000 mm.

- Piston stroke 3000 mm.

- Rate of climb / descent 500 mm/sec.

- Working speed 60 mm/sec.

- Total power of the motors installed about 800 kW (N° 03x250 kW + N° 01x50 kW)

- Capacity of the tank about 8.000 lt.

- Dimensions of the press about 3,000 x 1,100 x 12.000 mm. (W x D x H) - Dimensions of the tank about 5,000 x 2,500 x 2.800 mm. (W x D x H)

- Light between the shoulders on the operator side 2100 mm.

- Light between floors open 5000 mm.

- Piston stroke 3000 mm.

- Rate of climb / descent 500 mm/sec.

- Working speed 60 mm/sec.

- Total power of the motors installed about 800 kW (N° 03x250 kW + N° 01x50 kW)

- Capacity of the tank about 8.000 lt.

- Dimensions of the press about 3,000 x 1,100 x 12.000 mm. (W x D x H) - Dimensions of the tank about 5,000 x 2,500 x 2.800 mm. (W x D x H)